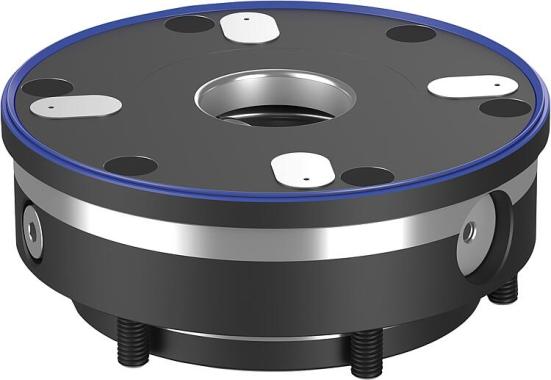

UNILOCK ESA 138 clamping module

UNILOCK clamping modules can be installed on machine tables or devices (plates, cubes, towers, etc.), with or without overhang, and in any position.

UNILOCK ESA 138 clamping modules are particularly suitable for automated clamping devices. The integrated sensor functions as well as the four offset support surfaces with air installation monitoring ensure the process reliability of the automated clamping devices. The “open/closed” position of the clamping slide and the control of the support of the clamping pallet can thus be detected on the clamping module. The dirt scraper prevents dirt from being deposited on the surface of the clamping module.

The pneumatic control of the clamping modules can be individual or collective.

This allows for a customized zero-point clamping system.

Their modular design makes it possible to optimally adapt the number and spacing of the clamping modules to the tightening operation to be carried out. Set-up times are significantly reduced, extending machine life.

The high clamping forces are produced by the integrated spring group (the unit is clamped without pressure).

The release is pneumatic.

Even with pressure drops or fluctuations in the compressed air supply, the tensile force is fully maintained.

All clamping modules have a turbo function by default. A brief pulse of air at the “Turbo” air connection significantly increases the traction force obtained by the springs. Clamping modules are therefore also very well suited to large machining jobs.

It is recommended to use the turbo function to obtain the maximum pulling force.

The following clamping forces are possible by combining UNILOCK clamping pins with M10, M12 and M16 fixing screws:

- Clamping force (M10) 35,000 N

- Clamping force (M12) 50,000 N

- Clamping force (M16) 75,000 N

Tightening force with CHC screw DIN EN ISO 4762 -12.9

The clamping pins may only be tightened in the clamping module in conjunction with a mounted replacement unit.

A clamping spindle size common to all clamping modules and compatibility with the 5-axis modular clamping system 80 guarantee varied possibilities of use.

Technical data: - Traction force with turbo of 28 kN.

- System pressure: 6 bars, lubricated air.

- Repeatability ≤ 0.005 mm.

- Temperature range from 5° to 60° C.

- Optional connection for purified air. Advantages: - Automable.

- “Open/closed” clamping slide detection function.

- Offset support surfaces with air installation control.

- Impurity scraper.

- Default turbo function.

- Repeat accuracy ≤ 0.005 mm.

- Positioning using short cones.

- High tensile forces.

- Optimization of equipment times. Accessories: - UNILOCK clamping tenon 42208, 42209, 42208-05, 42208-10.

- UNILOCK protective cap for clamping module 42796. Please note: Recommendation for the nominal diameter of the pipe:

- Up to four clamping modules, nominal pipe diameter of 6 mm.

- From five clamping modules, nominal pipe diameter 8 mm. Functional principle: The clamping modules can be connected via the connections on the base plate or directly via the threaded connection of the clamping module.

To ensure proper operation of the clamping slides, ventilation to the upper piston chamber must pass through the “Turbo” connection.

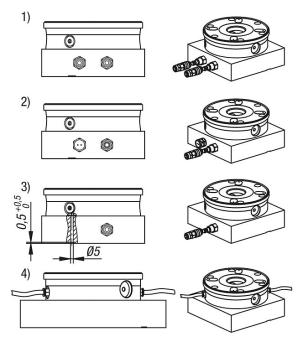

To do this, there are four options:

1) Connection and use of the turbo function in the base plate in addition to the "Open" connection. The clamping module can thus be tightened with a brief pulse of air if necessary. (Recommended)

2) A simple drilling to vent air in the base plate connected to the turbo fitting. To protect the bore against dirt, a vent plug should not be used with a fitting with a blocking function.

3) In the third case, the piston chamber must be ventilated by means of a bore connected to the base plate by a transverse groove. The drilling must touch the turbo connection for ventilation to be possible.

4) If the clamping module is operated from the side, the vent plug must be placed at this location. Scope of delivery - 1x clamping module.

- 2x O-rings Ø9x1.50 for fluid supply.

- 6x O-rings Ø9x1.50 for detection functions.

- 6x fixing screws.

- 6x cover covers for fixing screws. Drawing indication:

a) connection without pipe on the ground side (open position detection function of the clamping slide)

O-ring Ø9x1.5

b) connection without pipe on the ground side (Turbo)

O-ring Ø9x1.5

c) connection without pipe on the ground side (closed position detection function of the clamping slide)

O-ring Ø9x1.5

d) connection without pipe on the ground side (installation control) O-ring Ø9x1.5

e) connection without pipe on the ground side (open)

O-ring Ø9x1.5

f) side connection G1/8 (Turbo)

g) side connection G1/8 (opening actuation)

h) centering edge

i) vent

Français

Français