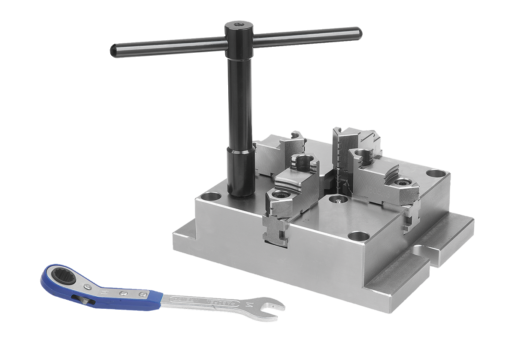

Stationary 4-jaw steel chucks

Stationary 4-jaw chucks are particularly suitable for centered clamping of workpieces on drilling and milling machines. The flexible arrangement of hard and soft clamping jaws allows easy clamping from the inside and outside of workpieces of different sizes and shapes.

Benefits :

The repeatability during centered tightening is 0.02 mm.

Flat shape.

For drilling and milling machines

Precision ground base body.

Optimal access to the lubrication system.

Large through bore for clamping rods.

Operation by hex key.

Quick and easy to use.

The soft jaws can also be screwed onto the base jaws.

Matter :

Steel.

Finishing :

Ground body contact surfaces.

Hardened, ground clamping jaws.

Note:

Observe the numbering when installing the clamping jaws.

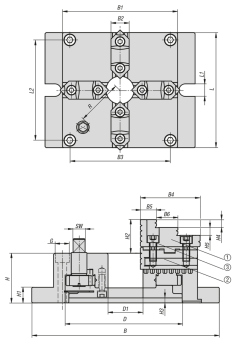

The jaw chucks are precision ground.

The tolerances of W, X, Y, Z between chucks are less than 0.05mm.

The repeatability during centric tightening with hard jaws is less than 0.02 mm.

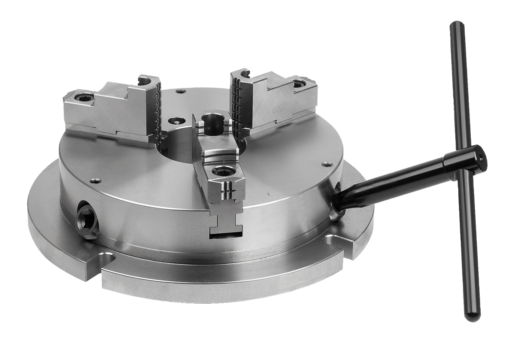

The sliding base jaws are driven by the pivot ring located in the chuck.

The slewing ring transmits force to the base jaws through the rotational movement of the threaded spindle and produces synchronous movement of the clamping jaws outward or inward.

Insufficient lubrication leads to excessive wear and reduced clamping force.

Make sure lubrication intervals are regular.

Benefits :

The repeatability during centered tightening is 0.02 mm.

Flat shape.

For drilling and milling machines

Precision ground base body.

Optimal access to the lubrication system.

Large through bore for clamping rods.

Operation by hex key.

Quick and easy to use.

The soft jaws can also be screwed onto the base jaws.

Français

Français