EISMO

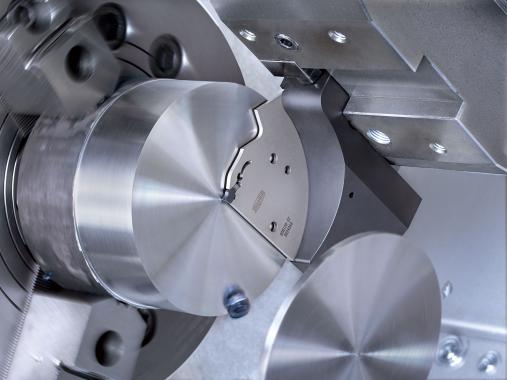

Automatic 2-axis CNC band saw - ERGONOMIC 290.258 DGA

Description

For straight and angled cuts at 45° ( left and right ) and up to 60° on the right.

Entirely streamlined machine mounted on a mechanically welded frame.

With hydraulic unit and lubrication device with tank and lubricant pump.

This machine is equipped with:

- Non-switchable 400 V TRI motor, power 1.5 kW, cutting speeds from 20 to 120 m/min.

- Electronic speed variator.

- Cast iron saw bow.

- Hydraulic cylinder ensuring the lowering and raising of the saw arm, with cutting force sensor on the back of the band.

- Material detection feeler when lowering the sawing head for automatic change from rapid approach to working speed.

- Hydraulic clamping vice automatically moving from left to right of the plate thanks to a hydraulic cylinder.

- The hydraulic vice of the bar advance ( mounted floating ) moves on 2 round columns and is driven by a toothed belt and a motor ( reading of the length on a magnetic ruler ).

- Machine stop device at the end of the bar or in the event of a loose bar.

- Ribbon tension indicator.

- 1500 mm long bar advance and multiple stroke repetition.

- Automatic pivoting of the saw head in connection with the bar advance ( pivoting by chain + electric motor, locking in position by hydraulic cylinder ).

- CNC control panel allowing different lengths to be programmed in the same bar. To each cutting length is attached a number of pieces and 2 pivoting angles of the head and a quantity of pieces.

Cutting capacities:

- Straight cut: Ø 258 mm - 325 x 180 mm - 250 x 258 mm - 258 x 258 mm.

- Bevel cut 45° to the right: Ø 210 mm - 215 x 100 mm - 180 x 250 mm - 195 x 195 mm.

- Bevel cut 45° to the left: Ø 180 mm - 235 x 80 mm - 145 x 245 mm - 165 x 165 mm.

- 60° bevel cut on the right: Ø 125 mm - 135 x 100 mm - 115 x 125 mm - 125 x 125 mm.

Tape dimension: 2910 x 27 x 0.9 mm.

Working height: 755mm.

Minimum cutting Ø: Ø 5 mm.

Minimum bar end length: 280 mm.

Dimensions ( L x W x H ): 2900 x 1850 x 1650 mm.

Machine weight: 1500 Kg.

Technical details

This machine is equipped with:

- Non-switchable TRI 400 V motor, power 1.5 kW, cutting speeds from 20 to 120 m/min.

- Electronic speed variator.

- Cast iron sawing bow.

- Hydraulic cylinder ensuring the lowering and raising of the sawing arm, with cutting force sensor on the back of the band.

- Material detection probe when lowering the sawing bow for automatic switching from rapid approach to working speed.

- Hydraulic clamping vice moving automatically from left to right of the table using a hydraulic cylinder.

- The hydraulic bar feed vice (floating mounted) moves on 2 round columns and is driven by a toothed belt and a motor (reading the length on a magnetic ruler).

- Machine stop device at the end of the bar or in the event of a loose bar.

- Ribbon tension indicator.

- Bar feeder length 1500 mm and multiple stroke repetition.

- Automatic pivoting of the sawing head in conjunction with the bar feeder (pivoting by chain + electric motor, locked in position by hydraulic cylinder).

- CNC control console allowing different lengths to be programmed in the same bar. Each cutting length is assigned a number of pieces and 2 pivot angles of the head and a quantity of pieces.

Cutting capacities:

- Straight cut: Ø 258 mm - 325 x 180 mm - 250 x 258 mm - 258 x 258 mm.

- 45° bias cut to the right: Ø 210 mm - 215 x 100 mm - 180 x 250 mm - 195 x 195 mm.

- 45° bias cut to the left: Ø 180 mm - 235 x 80 mm - 145 x 245 mm - 165 x 165 mm.

- 60° bias cut to the right: Ø 125 mm - 135 x 100 mm - 115 x 125 mm - 125 x 125 mm.

Ribbon size: 2910 x 27 x 0.9 mm.

- Working height: 755 mm.

- Minimum cutting Ø: Ø 5 mm.

- Minimum bar end length: 280 mm.

Dimensions (L x W x H): 2900 x 1850 x 1650 mm.

Weight of the machine: 1500 Kg.

Administrative documents

EISMO

Machining and material removalDescription

For more than 40 years EISMO has been the specialist in machines for cutting and machining ferrous metals (STEEL, STAINLESS STEEL) and non-ferrous metals (ALU, BRASS, COPPER). We sell band saws, milling saws, machining benches for long profiles, length stops, handling equipment for ALU carpentry, angle crimpers... We thus cover practically all t...

Français

Français