AMOB

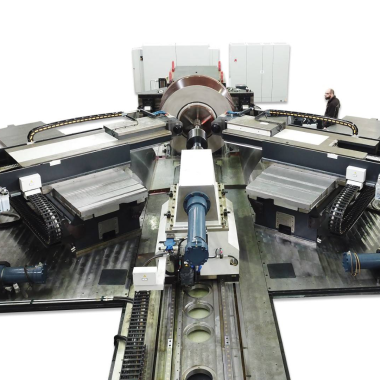

eMOB - 2 BEND

The main feature of this range is the change of bending direction by rotating the bending head.

It is capable of processing tubes from 5mm to 63mm outside diameter (OD) and has a multiple stacked tool capacity.

Our eMOB 2 Bend Series is defined as tube bending excellence, where quality control, versatility and production precision are carefully studied and refined by our team every day.

These machines are distinguished by the production of left/right bends in a cycle, with bend eraser support, allowing the production of bends combining quality and precision in tubes with tighter bending radii and larger diameter/thickness ratios.

Fully electric CNC tube bending machine , Left / Right reversible , designed to produce fixed and variable radii on various tube formats and profiles such as round, square, rectangular, oval and different sections.

The machine allows to bend several radii in the useful height of the tool stack thanks to the vertical and horizontal servomotor movement of the head. It also offers the possibility of obtaining a variable radius via the push bending carried out by a carriage booster.

The horizontal and vertical servomotor movement of the bending head allows unlimited position adjustments, making it possible to bend profiles with complex shapes, with fine adjustments guaranteed by the precision of the servomotors and reduced cycle times.

·

Tube positioning device by carriage, feeding and orientation

·

Quick tool change system with automatic repositioning (CNC) of all tool support devices

·

Left and right bending direction

·

Interchangeable shaft system for non-standard bending radius

·

Control of 11 digital working axes (CNC), with the possibility of controlling up to 16 axes

·

Ability to accept clamping dies with integrated radii

·

Emergency stop on the bending arm

·

CE safety enclosure and light curtain

·

Reduced programming time

·

Reduction of tube end waste

·

Minimized maintenance and repair costs

·

Optimal user ergonomics

·

Easy to use

·

Energy gain

·

Latest generation technologies

·

Quick chuck connection system

·

Localized automatic lubrication

Français

Français