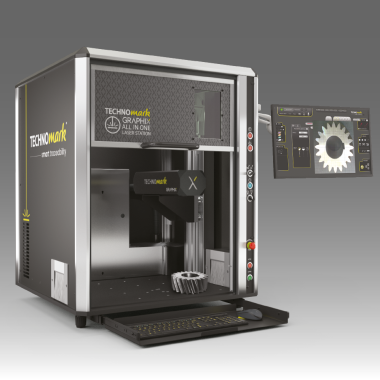

TECHNOMARK

Integrated micro-percussion marking machine - Tempo

The Tempo

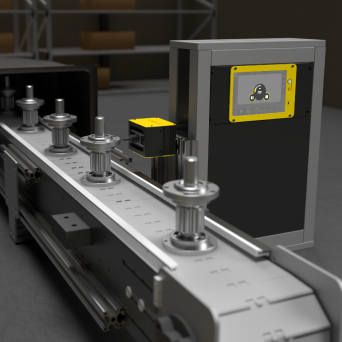

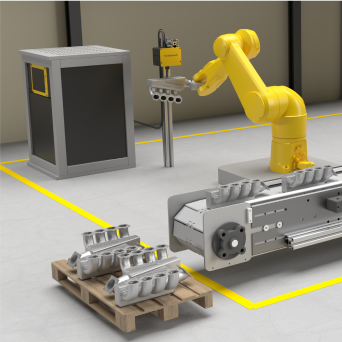

marking machine is part of the Inline.series range designed for integrated

use. It uses dot peen technology

(deformation of the material by a succession of impacts) to guarantee permanent

marking.

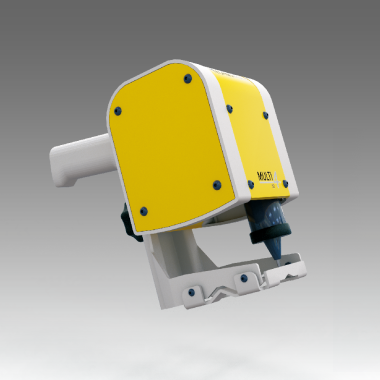

Designed for

integrated use, the Tempo marking machine is easy to integrate into a

production line. Its compact marking head with detachable cables has 3 fixing

faces and can be used at 360° (multi-position). The controller has a

front-mounting system for panel mounting, as well as a universal VESA 100 mount

on the back to adapt to the widest possible range of brackets. The machine

requires just one source of energy to operate: electricity.

Tempo is

perfectly suited to the productivity requirements of integration, as it has

been designed to operate continuously, i.e. 24 hours a day, 7 days a week. In

terms of performance, it can mark up to 3 characters per second. Its aluminium

frame and integrated protective bellows give it the robustness needed for

intensive use.

To exchange

data with an internal network or control the machine using a field network

(Ethernet IP or Profinet), Tempo has a network connection via its Ethernet

ports. This also allows you to benefit from the switch function.

Tempo is

also equipped with a 16-channel card that can be fully configured in a

dedicated module accessible in administrator mode. The large number of

inputs/outputs not only saves users money on the overall budget, but also saves

time during commissioning.

To ensure

ease of use, the Tempo controller is equipped with a 10" touch screen and intuitive

control software for creating marking files and much more. It is possible

to manage the course of the impact unit to adapt it as closely as possible to

the shape of the parts: limiting the size of the marking window or adding path

points, for example, to avoid obstacles. The software is also capable of

managing local and global variables, and providing real-time information thanks

to its maintenance module.

Several

types of user profile are available: administrator, supervisor and operator.

They are used to control the various accesses to the machine: file creation,

machine settings, maintenance, etc. Individual accounts with badge or password

access can also be created.

For even

more functionality, a range of additional licences (production tracker, marking

authorisation control, etc.) can be added.

Finally, the

controller can be connected to a code reader to fill in variables, open files

or reread markings.

There are a wide

range of marking options: alphanumeric, timestamping (shift changes, dates,

etc.), logo, Datamatrix, etc., and they can be applied to parts of all shapes

and sizes.

Would you

like to find out more about our integrated dot peen marking machine? Contact

us! Our sales team will advise you on the traceability solution best suited to

your needs.

-

Marking window: 30 x 60 mm and 120 x 60 mm

-

Head 30: 170 x 124 x 132 mm

(H198 mm with impact unit); 3.2 kg

-

Controller: 310 x 66 x 217 mm; 1.5 kg

-

Connectivity: 3 USB ports, 1 x

16 I/O card, up to 3 Ethernet ports

-

Head/controller cable: 10 m

-

Technology: dot peen

Français

Français