SINTERED MECHANICAL PARTS

Unlike traditional metallurgical processes, which always intervene the solidification of a molten metal, sintering starts from a metallic powder.

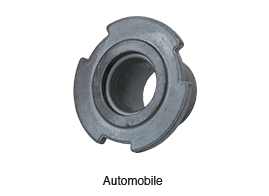

Around 1908, the first self-lubricating bushings appeared. Then in 1935, automobiles began to use sintered mechanical parts.

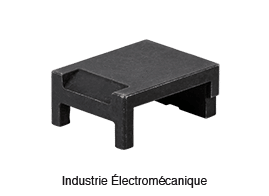

Powder metallurgy, or sintering, makes it possible to obtain parts with a high geometric precision, from a few grams to several hundreds of grams, and able to withstand significant mechanical stress.

Sintering is particularly suitable for medium and very large series.

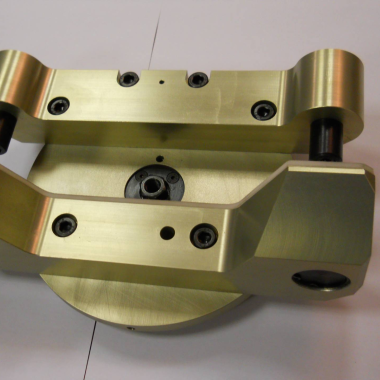

Compaction or compression

Presses can be mechanical, hydraulic or electric, the choice of press power will depend on the part to be compacted. At Porite the powers range from 0.5T to 1,600T.

The compaction equipment is filled by gravity. It is made up of a matrix (exterior geometry of the part) of upper and lower punches. Their number will depend on the design of your part and the type of press used. This first operation will give the geometric shape of the part, but without the required mechanical characteristics (green part).

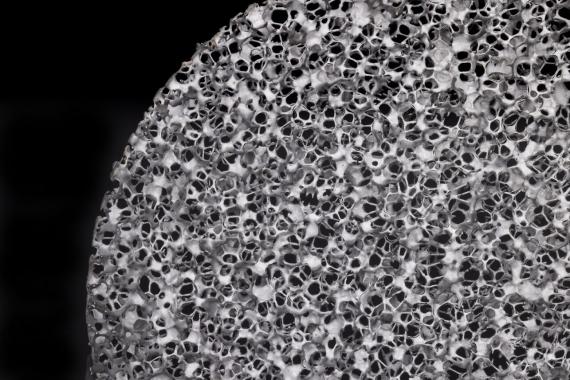

Sintering

From a practical point of view, the sintering operation must meet 3 expectations:

- Confer the mechanical properties to the compacted part (green part).

- Maintain dimensional accuracy as much as possible (nominal dimension and tolerances)

- Be as economical as possible

- The sintering temperature is between 1120°C and 1135°C, some parts require high temperature sintering from 1200°C to 1350°C, under a protective atmosphere.

The sintering temperature is typically between 1120°C and 1135°C. Some parts require high temperature sintering from 1200°C to 1350°C. The sintering atmosphere is adapted to the material of the parts.

Calibration

The sintering operation causes an increase in dimensional dispersion and shape defects.

If the sintered part no longer meets the requirements of the plan, calibration on the press may be necessary.

Compaction or compression

Presses can be mechanical, hydraulic or electric, the choice of press power will depend on the part to be compacted. At Porite the powers range from 0.5T to 1,600T.

The compaction equipment is filled by gravity. It is made up of a matrix (exterior geometry of the part) of upper and lower punches. Their number will depend on the design of your part and the type of press used. This first operation will give the geometric shape of the part, but without the required mechanical characteristics (green part).

Sintering

From a practical point of view, the sintering operation must meet 3 expectations:

- Confer the mechanical properties to the compacted part (green part).

- Maintain dimensional accuracy as much as possible (nominal dimension and tolerances)

- Be as economical as possible

- The sintering temperature is between 1120°C and 1135°C, some parts require high temperature sintering from 1200°C to 1350°C, under a protective atmosphere.

The sintering temperature is typically between 1120°C and 1135°C. Some parts require high temperature sintering from 1200°C to 1350°C. The sintering atmosphere is adapted to the material of the parts.

Calibration

The sintering operation causes an increase in dimensional dispersion and shape defects.

If the sintered part no longer meets the requirements of the plan, calibration on the press may be necessary.

Français

Français