Parts in pressure die casting

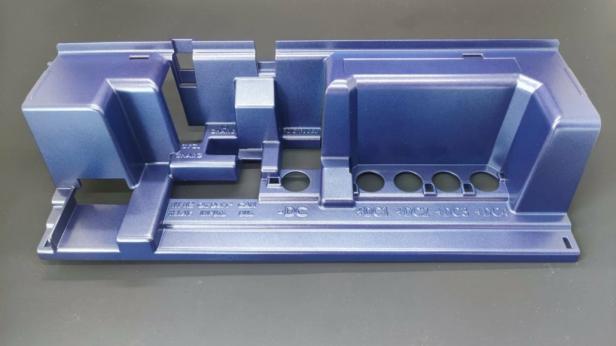

Looking for the ideal supplier for the production of your parts in pressure die casting? AGC , with 20 years of experience in the field in China, offers you its expertise for solutions at low-cost mold prices , very low injection costs and very competitive finishing (deburring, machining, surface treatment, packaging)

The foundry makes it possible to achieve very low part costs, however the investment in tooling is very substantial (several tens of thousands of euros), we offer our customers a substantial gain with tooling costs of 30 to 50% cheaper and guaranteed quality parts. Send us the details of the parts you want to make, we will send you a tooling + parts offer delivered on site very quickly.

Our capabilities in pressure die casting

- Presses up to 2000 T

- Pieces from ten grams to more than 10kg

- Subjects offered:

- Aluminum (AS9U3/ AS12U/ AS10G/ DM23 etc.)

- Magnesium

- Zamac

- Possibility of anodizing, neutral, black or color

- 3 and 4 axis machining centers

- Assembly possibilities

WHAT IS DIE CASTING?

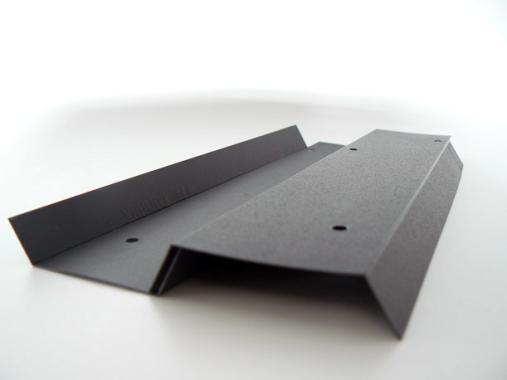

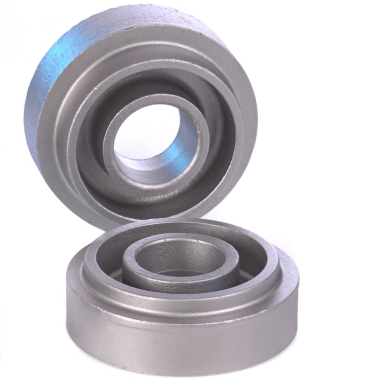

Pressure casting is a technique for producing non-ferrous metal parts at high speed, in the order of a few seconds per part, by injecting liquid material at high temperature and high pressure into a tool. The material then cools and returns to its solid form, following the shape of the injection mould. The process allows highly automated production, with the same tool being able to be used for more than 100,000 injections.

Pressure injection, which comes to us from the automotive industry, is also widely used in other applications, such as electronics or aeronautics.

ADVANTAGES OF DIE CASTING

- The speed of production of the parts allows very low unit costs compared to other manufacturing methods

- The rise and pressure resistance of the tooling makes it possible to make complex shapes that gravity casting cannot achieve

- It is possible to achieve wall thicknesses of less than one millimeter: grain of weight and material not negligible in certain industries

- The parts produced are precise, of the order of a hundredth of a millimetre.

- Good surface condition of parts after injection

- Due to the automation of production, very high repeatability from one part to another

DISADVANTAGES OF PRESSURE INJECTION

- High tooling and setup costs (injection settings)

- To improve the fluidity of the material, injected aluminum is rarely pure, which can cause appearance problems (stains), especially during color anodization. AGC can also offer you a choice of material in order to carry out a colored or black anodization on your die-casting parts.

- Presence of draft angle

- Presence of micropores in the material

Français

Français