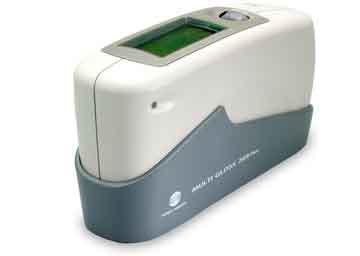

CM-3610A Benchtop Spectrophotometer

The CM-3610A incorporates Konica Minolta's patented digital technology for specular reflection control, a mathematical technology that does not use a mechanical trap. By successively switching on two xenon arc lamps, the system simultaneously delivers measurements in SCI mode (specular reflection included) and in SCE mode (specular reflection excluded). Accurate measurement of materials such as paper or fabric treated with fluorescent whitening agents (FWA) – optical brighteners – requires precise control of the UV component and its effects. The patented digital UV control method used by the CM-3610A allows such control by using Konica Minolta's own calculation methods to combine the results of the flashes of the two xenon arc lamps: one with a UV emission of 100 % and the other without UV emission (cutoff at 400 nm or 420 nm). This method eliminates the need for positioning a mechanical UV filter and repeating position adjustments. It allows instant UV adjustment by CIE whiteness index, CIE tint, ISO whiteness (brightness), or UV profile (spectrum). The vertical design of the CM-3610d makes it very simple to measure papers, textiles, powders: easy positioning, and cleanliness of the device guaranteed. The piston slides vertically in order to place the sample, whether rigid or flexible, and then press it against the measurement opening, the pressure roller being mounted on a ball joint. The CM-A134 accessory for opacity measurement comes very easily to cover this piston to replace the original pinch roller, its reversible black/white bottom then allowing a very easy double measurement. The viewfinder provides a clear and bright view of the sample placed on the measurement port in order to perfectly position it before measuring it. The CM-3610A has 3 measuring apertures - Ø 4mm, 8mm, and 25.4mm - to accommodate specimens of all sizes. - Automotive, aeronautics - Plastic - Painting - Pharmaceuticals - Cosmetics - Chemistry

Reflection mode: di:8°, de:8° (diffused illumination, detection at 8°), simultaneous measurements in SCI (specular reflection included) and SCE (specular reflection excluded)

Français

Français