Maintenance of equipment and hydraulic components: ultrasound, the winning solution.

Ultrasonic measurement for the maintenance of your equipment and their hydraulic components is a solution that allows a wide range of controls in this field of application. Ultrasound makes it possible to locate internal leaks on valves, industrial valves and steam traps. Ultrasonic measurement is also used for preventive maintenance of pumps; bearing checks, alignment, lubrication optimization and cavitation detection.

In short, ultrasound can be used in all industrial sectors. They are used both in the context of condition-based/preventative maintenance and in reducing costs linked to energy expenditure.

The range of SDT ultrasonic measuring devices and associated sensors presents a user-friendly and versatile solution that ideally meets the needs of maintainers; simple to use for those who want it and more advanced for those who need it.

Challenges and control of the maintenance of hydraulic equipment and components:

Among all the installations on a production site, hydraulic equipment and components certainly constitute a very important availability issue.

A security issue too, particularly for French nuclear power plants which use SDT ultrasonic detectors to control all of their industrial valves, but also security valves in the field of oil and gas refineries (TOTAL), or petrochemicals (SANOFI, ARKEMA, BASF, etc.).

When organizing preventive maintenance on an industrial site concerning hydraulic pumps, some companies could not produce without water supply. In France, the few sectors of activity which are basic chemistry, the production of synthetic yarns/fibers, the paper and cardboard industry, metallurgy, parachemistry and the pharmaceutical industry, alone total the two thirds of industrial water consumption. [1] And the stakes are just as high in pumping stations for drinking water networks.

1. Detecting internal leaks in valves is often a crucial issue.

Faucets refer to devices mounted on a network. Its function is to modify, maintain or interrupt the passage of a fluid. Ultrasonic measurement identifies faulty valves, valves and flaps, without stopping or dismantling. Internal failures or leaks in a valve are synonymous with financial losses. More serious, they also have dramatic consequences on the safety and quality of production. Without a suitable tool, their periodic verification remains a delicate point.

Ultrasound, a quick and non-intrusive method

Systematic dismantling as a preventive measure is definitely unsuitable. This strategy proves to be long and costly and ultimately only detects the few leaking valves responsible for the losses. Conversely, ultrasonic detection is the autonomous, rapid and above all non-intrusive field solution. No more need for disassembly, no more need to wait for production to stop.

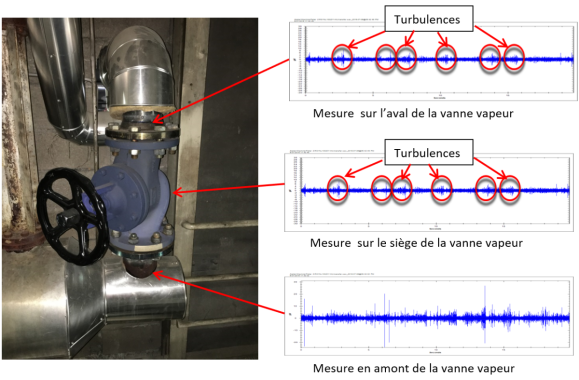

The leak generates a sound

The internal leak of a valve results in the unwanted passage of fluid downstream. As the fluid escapes, it rubs against the valve seat and produces turbulence. Both phenomena emit a sound. The transmitted frequency is wide. However, it is essential to work in the ultrasonic range, generally 40 kHz, in order to reduce the influence of the background noise of the installation.

Simple and quick implementation

With the SDT detector, control consists of placing a contact sensor at three points: upstream, on the seat and downstream of the valve. The diagnosis is quick and immediate, based on the comparison of the 3 measurements. A rise on the valve seat indicates that the valve is leaking. There will be confirmation by listening: the operator will actually hear the leak.

Data management is simplified by memorizing measurements and their processing on the Ultranalysis® Suite software with the edition of reports, alarms, forgotten measurement points, rounds. An ATEX version is available for risky environments.

Continue reading: https://sdtultrasound.com/fr/2023/11/30/maintenance-des-equipements-et-des-compolitiques-hydrauliques-les-ultrasons-la-solution-gagnante/

Our other news

See allJoin the largest community of industrial suppliers

- Helping you with your ongoing technology watch

- Provide you with detailed supplier statistics

- Give you international visibility

Discover the largest catalogue of industrial products on the market

- To offer you the best catalogue of industrial products on the market

- To guarantee you a 100% secure platform

- Enable you to have live remote exchanges

Français

Français