TANK 1000 EVO

The new Tank EVO line encompasses more than 40 years of MCM technological know-how, will be available in 5-axis version, and can also be configured for Multitasking machining such as turning and grinding.

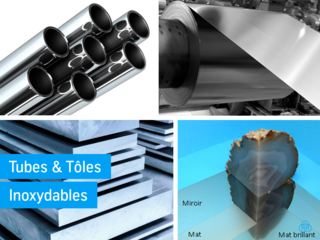

Tank 1000 EVO expands the application possibilities of the Tank family, thus making available to customers in every industry the capabilities and features that the company has developed over the years for the high-demanding Aerospace industry. In fact, the features of the new horizontal machining center open up new application opportunities with solutions suitable for general mechanics, model making and mold making, where component sizes and work volumes are smaller, but flexibility and machining with multiple simultaneously coordinated axes are required.

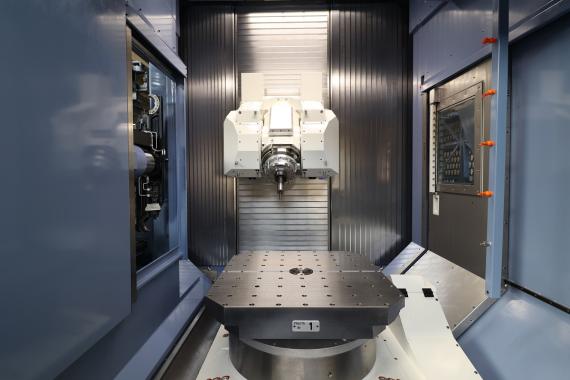

Tank 1000 EVO, in fact, is a 5-axis machining center with high table load capacity and is available with two different head types. The tilting head as A-axis, which allows for a very remarkable negative-axis working set; the dual motorization in the head structure, which provides optimal behavior in turning and grinding operations. The tilting head as B-axis, instead, enables sculpting and modeling machining, more related to industries such as mold making. In addition, high-performance electrospindles have been designed to maintain constant machining accuracy over time.

All linear axes are equipped with a direct measuring system through high-precision optical scales, while rotary axes are equipped with absolute measuring systems through large encoders to minimize possible angular errors.

The FEM analysis study of moving masses allowed MCM to optimize the structure of the new Tank 1000 EVO, giving it maximum stiffness and consistent precision, while achieving higher dynamics, acceleration and speed even when machining with a weight on the machine pallet up to 2,500 kg. The reduction achieved in energy consumption is also sizable. The solid structure of the machine consists of base, X-axis upright and Y-axis column. Positioning on dual level of X-axis guides ensures stiffness and thrust resistance in heavy duty machining. The overall size and height of the machine have been reduced by about 25%, even if the working volume has been increased.

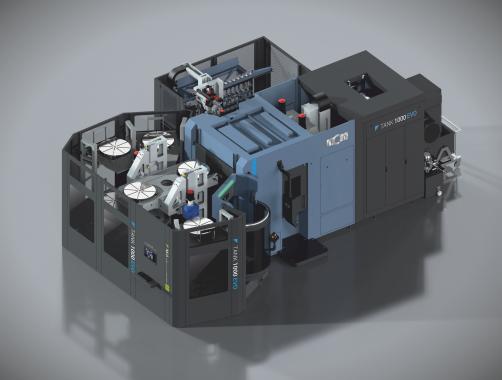

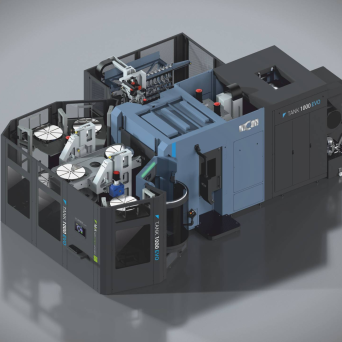

The Multipallet system features vertical movement to handle two storage levels. The extensive pallet availability and an adequate number of tools in the modular magazines ensure high hourly occupancy, improving efficiency and productivity. Pallet capacity ranges from 9 to 15 (optional) and can also be expanded after-sales. Fast returns on investment and management of significant production volumes consisting of small to medium batches are the benefits of the Multipallet and FMS automation systems by MCM, into which all the machines of the new Tank EVO line can be integrated.

Tank 1000 EVO can also be configured for multitasking machining, such as turning and grinding, and features full digital equipment, with software platforms for supervision, diagnostics and predictive maintenance - jFMX and jFRX, produced by MCE Solutions, the IT division of MCM - making flexibility and production efficiency a reality.

Français

Français