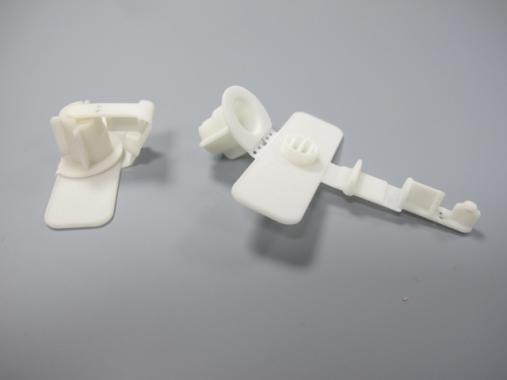

FDM - Thread Deposit

FDM (Fuse Deposit Modeling) or FFF (Fabrication en Fil Fondu).

Wire Laying is an additive technology: manufacturing by adding material (high temperature wire deposition) of operational prototypes or small series of variable sizes. This technology allows the use of various thermoplastics (basic, technical or meeting very specific needs). Thanks to this manufacturing method, your future injected parts will be produced from the prototypes in their standard materials.

Materials available: • Natural, coloured, translucent or fireproof ABS (electronic boxes, stereo, household appliances)

• ABS loaded with kevlar, carbon, aluminium, bronze, copper… (robotics, drone, military)

• ABS/PC (protective casing, battery pack)

• Natural or translucent PC (protective helmet, impact parts)

• Nylon (flexible parts, high resistance)

• POM (gliding pads)

• Carbon-filled PETG (high mechanical resistance)

• WOOD (coconut, olive, ebony, bamboo… for architecture or furnishing design)

• PET without bisphenol A, RoHS and REACH certified and compatible with food contact according to the American FDA standard.

Français

Français