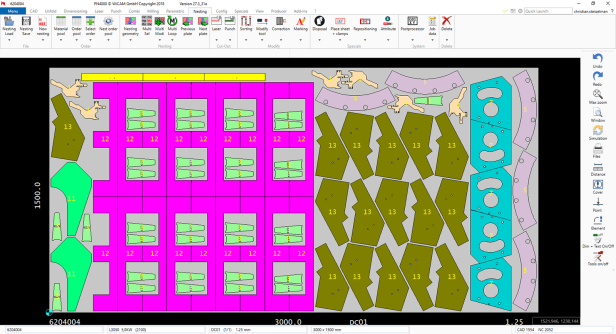

Maximum material savings thanks to WiCAM software

Access a world of maximum efficiency with our advanced Power Nesting solution. Since last year, we have been offering our customers an AI-assisted nesting strategy in PN4000 that saves up to 10% material compared to usual nesting strategies.

In an interview, Guido Herz, an expert in manufacturer-independent CAD/CAM and nesting systems, talks about the advantages and operation of WiCAM's "Power Nesting" nesting solution. Find out first-hand how this innovative method can help you optimize your working methods and achieve your goals more efficiently.

What is most important in a nesting strategy?

The most important thing in nesting is efficient material management. The more effective my strategies are, the more coins I can obtain from my raw material and therefore increase my profits. To do this, different parameters such as entry and exit trajectories must be taken into account. It has been proven that the differences between regular nesting and Power Nesting can be up to 10% per order. The particularity of the “Power Nesting” nesting solution is its dynamic adaptation capacity, depending on the predefined time parameters in which the nesting result must be available.

For which machines is the “Power Nesting” solution suitable?

The “Power Nesting” nesting solution is suitable for all machines that cut with a beam, whether laser, plasma or water jet. This is where Power Nesting can make all the difference and achieve optimal results.

What are the ideal parts for the Power Nesting solution?

The “Power Nesting” nesting solution is particularly interesting if you regularly produce small series and want to nest a large number of different parts. The particularity of this nesting process lies in the algorithms which dynamically adapt and test as many parameters as necessary according to the allotted time in order to obtain the optimal nesting result.

How does the Power Nesting solution work?

While traditional nesting first places large parts on the sheet metal and then nests small parts around it, the Power Nesting solution works differently. It continuously moves all parts dynamically until the optimal result is achieved for each sheet. In addition, the “Power Nesting” nesting solution makes it possible to manage several sheets at the same time, which makes it possible to optimize overall work on several sheets. This approach has the advantage of not using all the filler parts from the start, but of having filler parts right down to the last sheet, which allows for an overall more efficient use of materials across the entire job.

Conclusion

Compared to many other software publishers, WiCAM not only offers optimal nesting, but also the possibility of controlling your production directly from your ERP system, regardless of the manufacturer. Whether you have a Trumpf, Bystronic, Amada, Mazak, LVD laser or another CNC machine, WiCAM will allow you to control all manufacturers. The return on investment (ROI) of the Power Nesting solution is generally less than 6 months. This is evaluated beforehand by WiCAM in an online demo. After this demo, all customers with the latest version of PN4000 have the opportunity to test the new strategy for free for one month with their own parts.

Discover the future of manufacturing with our AI-powered nesting strategy and maximize your productivity while reducing your environmental footprint. Contact us to learn more and take your production to the next level!

Our other news

See allJoin the largest community of industrial suppliers

- Helping you with your ongoing technology watch

- Provide you with detailed supplier statistics

- Give you international visibility

Discover the largest catalogue of industrial products on the market

- To offer you the best catalogue of industrial products on the market

- To guarantee you a 100% secure platform

- Enable you to have live remote exchanges

Français

Français